Cost-efficient lightweight construction in automotive engineering through thermoforming and injection molding of Organosandwich semi-finished products

Innovative semi-finished Organosandwich products consisting of a thermoplastic honeycomb core and fibre-reinforced skin layers with thermoplastic matrix (organo sheets) can be produced in a continuous process and are therefore much more cost-effective than sandwich structures with conventional core materials (e. g. expanded honeycomb cores). A skin layer of fabric-reinforced organic sheets or thermoplastic laminates made of UD single plies makes it possible to produce application-optimized and load-bearing sandwich structures suitable for mass production. For use in complex components, these Organosandwich semi-finished products must be formed and, if necessary, further functionalized. In the research project Organosandwich it could be shown that this is feasible. The present article gives a brief overview of the insights gained.

Processing of Organosandwich

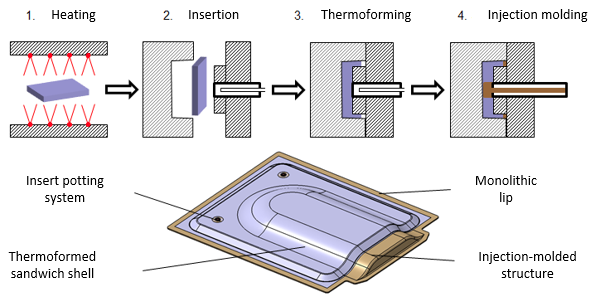

For high-volume applications, the further processing of the Organosandwich semi-finished products can be fully automated in the hybrid injection-molding process. This semi-continuous production process makes it possible to produce functionalized ready-for-use sandwich components within a short cycle time in four consecutive process steps (Fig. 1).

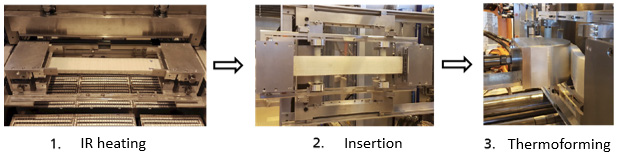

In the first process step, a flat sandwich semi-finished product is contactlessly heated on both sides by medium-wave infrared (IR) lamps. Here, a defined temperature profile across the sandwich cross-section is set. After heating, the highest temperature is found in the two face layers of the sandwich composite. These must be heated above the melting temperature of the thermoplastic matrix to ensure their formability and also the bonding of the injection- molding material during hybrid processing. Once the semi-finished product has reached the thermal state which is optimal for further processing, an industrial robot inserts it into the mold cavity. This transfer step must be performed very precisely and at high speed to avoid premature equalization of the cross-sectional temperature profile before thermoforming.

Thermoforming of the flat sandwich semi-finished products into shell-shaped structures takes place during the closing movement of the injection mold. In the first place, the desired shell geometry is formed here while retaining the core thickness. Secondly, shortly before the mold is completely closed, the core is pressed into a monolithic laminate at the edge of the component. This can be used both for component integration as a joining surface for welded, adhesive or rivet connections and so on as well as for injecting-on additional component functionalizations. The formed sandwich shell is functionalized after complete closure of the mold cavity and when a predefined closing force is reached in the conventional injection molding cycle.

Thermoforming

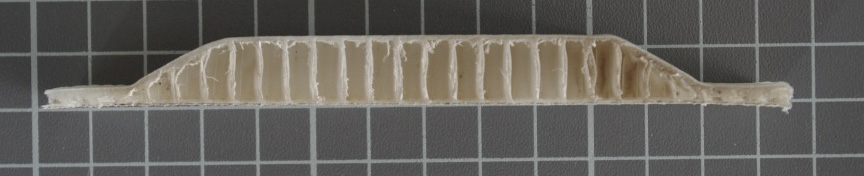

The thermoforming of flat Organosandwich semi-finished products requires a plastic deformation capability of the honeycomb core and of the endless-fiber-reinforced skin layers in the thermoplastic sandwich composite. For this reason, the semi-finished sandwich product must be heated in a defined manner and put into a state which allows a controlled deformation of the composite structure. As with the thermoforming of fabric-reinforced organic sheets, the thermoplastic matrix of the top layers must be heated to a temperature above their melting point. The challenge in heating the sandwich composites is now to heat the integrated thermoplastic honeycomb core so that it can be plastically deformed. At the same time, however, the core still needs to have enough residual compressive strength to accommodate the pressure loads encountered in thermoforming the desired shell shape. For this reason, the heating behavior of sandwich semi-finished products made from PP honeycomb core with 80 kg/m³ density (THPP80-10/8) and PP-GF60 cross-ply skin layers (made of single layers of UD tape with 60 wt.% fiber content in the 0/90 laminate lay-up) was investigated first both experimentally and numerically using a medium-wave IR radiation oven.

A test rig was designed for fundamental studies of thermoforming behavior and technologically implemented and could be used for investigating different geometries and forming processes. In the first step, the 2D thermoforming of flat sandwich strips was examined with the aid of a cylinder-shaped die (see Fig. 2). This made possible differentiated analyses of the deformation capability and deformation mechanisms of the sandwich composite semifinished products with respect to their anisotropic mechanical properties. The sandwich strip supported on two rollers is undergoes forming by the die moving in the thickness direction. Here constant feed and draw-in forces can be applied to the skin layers of the sandwich test piece so as to prevent creases forming on the inside of the radii.

To study the thermoforming process under realistic process conditions, it is possible to carry out the tests in a vertical installation position in a KM200 vertical injection-molding machine adapted for research purposes. Forming forces during the die movement can be captured by force sensors. Accurate control of the die advance is possible due to the compression function of the machines.

It was found that the honeycomb core in the W direction (longitudinal to the folding direction) and the L direction (transverse to the folding direction) exhibited good and approximately similar formability. In the W direction the core at plastic deformation of the cell walls allows a reorientation of the individual cells, and thus greater degrees of forming.

Edge melting

In addition to the design freedom in the shape of the component, the provision of joining concepts is an important aspect in establishing endless-fiber-reinforced thermoplastic sandwich composites as structural components in high-volume applications. With sandwich structures relatively great effort is necessary for the preparation of the joint locations in order to connect them using established joining methods such as welding, riveting or adhesive bonding, for example, to load-bearing structures.

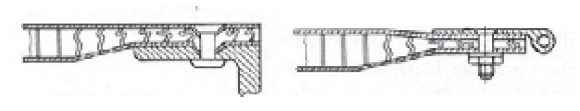

Fusing the skin layers into a single monolithic laminate is a method which makes it possible to prepare the joint location on sandwich structures. In this way the joining processes mentioned can then be used without additional connection profiles. The skin layers can be brought together into a single monolithic laminate especially at the edges of sandwich structure components. A chamfer can serve as a transition between the sandwich structure and the monolithic edge and should have a slope not exceeding 30°. In this way, under loading conditions the flow of force can be routed from the two top layers via the core, with decreasing magnitude, into a load-bearing structure.

During hybrid processing of the organosandwich semi-finished products, compression of the edges of the sandwich composite into a monolithic laminate can be done in addition to the thermoforming. In this regard validation tests have already been conducted with the test rig and a specially designed die. In the tests, all round its edge a flat Organosandwich test piece was given the chamfer geometry shown fig.4.

Heating in the IR radiation oven is carried out with the same heating regime which is used in thermoforming the shell geometry. However, at the end of the mold closing movement during the compression process the heat stored in the face layers is used to initiate under increased pressure a systematic melting of the honeycomb core to create the monolithic laminate.

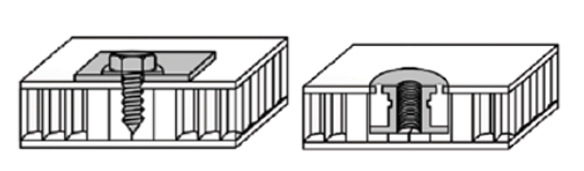

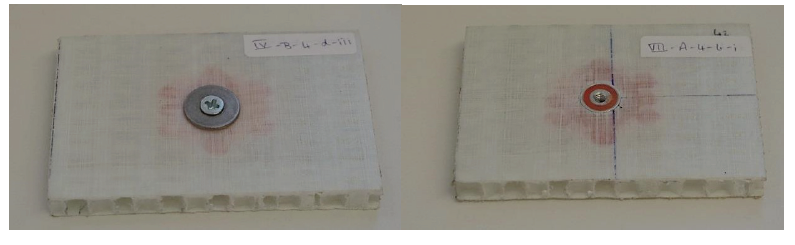

Injection molding of punctiform load-introduction elements

The relatively low strength of FRP sandwich structures in the thickness direction requires special adaptations in the joint area for punctiform load transfer, for example, by means of screws. Different connecting concepts may be found in the literature, which are applied depending on the load and application case. For medium and high loads the core structure must be reinforced locally, which can be done, for example, by filling the core with a curable resin-catalyst compound, known as potting. Depending on the load case, additional metallic inserts are embedded in the potting material (see Fig. 5).

During the processing of Organosandwich semi-finished products in the hybrid injection molding process, it is possible to use injection molding and thermoplastic for the potting fillings. It has already been demonstrated in experimental studies that a reproducible filling of a previously prepared core area by means of an adapted injection-molding cycle is possible within a few seconds. As an injection-molding material for the plastic potting, polypropylene with an MFI of 23g/10min, appropriate for the matrix material of the Organosandwich semifinished products, was processed in the experiments. Not only could pure potting fillings be produced by injection molding but metallic inserts could also be embedded in the sandwich.