ThermHex Organosandwich

The patented ThermHex production process

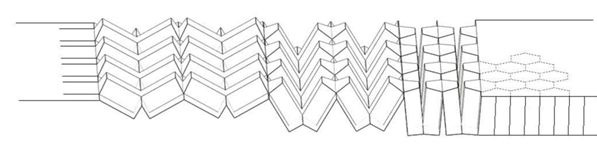

The ThermHex process, patented by EconCore NV in Leuven, enables thermoplastic honeycomb cores to be produced in continuous in-line production. In other methods, every layer of honeycomb must be cut individually from a block and then laminated. This makes the conventional production methods for honeycomb cores both complex and expensive – with ThermHex, all production steps take place on a single production line.

After extrusion, the web is rotationally vacuum-formed, unfolded, laminated and cut to the length desired by the customer. At the production facility in Halle, honeycomb cores with a thickness of 3 to 30 mm and an individual length of up to 6 meters can be produced, production speeds reaching up to 10 meters per minute.

The honeycomb cores are processed in particular by the fiber-composite industry into sandwich panels and components, which are used, for example, in truck bodies, in the automotive interior or in prefabricated bathrooms and in swimming pools.

The process is more resource-efficient and significantly less expensive than conventional honeycomb core manufacturing processes. Thanks to this process, ThermHex Waben GmbH is able to produce honeycomb cores in large quantities at significantly lower costs. Since the start of production in 2010, it has been able to continuously increase its production volume up to a present 500,000 m²/year.

Innovative Organosandwich semi-finished products

Innovative Organosandwich semi-finished products consisting of a thermoplastic honeycomb core and fiber-reinforced skin layers with thermoplastic matrix (organic sheets) can be produced in a continuous process and are therefore much less expensive than sandwich structures with conventional core materials (such as expanded honeycomb cores). By applying a skin layer of fabric-reinforced organic sheets or thermoplastic laminates of UD single layers, application-optimized and load-adapted sandwich structures suitable for large-scale production can be produced. For use in complex components, these Organosandwich semi-finished products must be reshaped and where applicable further functionalized. In the Organosandwich research project the feasibility of this has been demonstrated. This contribution gives a brief overview of the findings.

Sandwich structures have very high weight-specific stiffnesses and strengths. With skin layers made of fiber-reinforced plastics and a lightweight plastic-based core (foam or a honeycomb core, for example) high-strength structures can be realized in, among other things, aircraft construction, shipbuilding or wind turbine rotor blades. For large-area structures mainly subject to bending loads, sandwich construction permits an enormous potential for saving weight. By using a lightweight core material that keeps two thin skin layers apart, weight savings of more than 80% are possible compared with a monolithic construction. Here the thickness of the skin layers can be just a fraction of the thickness of a monolithic material. In this way, in addition to the weight savings, significant material cost savings are also possible. Common processing methods, such as the prepreg or vacuum infusion process in which the material components (skin layer and core) are introduced separately into a mold and then joined together are, however, very time-consuming and costly and therefore hardly suitable for mass production. For this reason, foam injection-molding methods have for some years been investigated with regard to the production of thermoplastic sandwich structures. The combination of thermoplastic foams and endless-fiber-reinforced face sheets makes heavyduty lightweight sandwich constructions possible. It is therefore predestined above all for use in structures where weight is an important consideration, such as in the construction of electric vehicles.

Mechanical testing and material characteristics

Basic characterization of the mechanical behavior of Organosandwich semi-finished products with ThermHex honeycomb cores and 2-ply cross-ply skin layers consisting of UD-tape individual layers (PP-GF) was carried out by out-of-plane compression and shear tests as well as flexure tests with specimen pieces taken from flat sandwich panels. Here the specimens were statically loaded to failure with the help of a universal testing machine, and stiffness and failure loads determined.

Compression tests

The compression tests were carried out on specimens with a square cross-section in accordance with ASTM 365M. During the test, the load displacement curve of the test machine was recorded. In addition, the relative displacement of the two stiffly mounted compression dies and also the elongation of a side-gated lateral surface of the specimen were measured with the help of the gray-value correlation system ARAMIS.

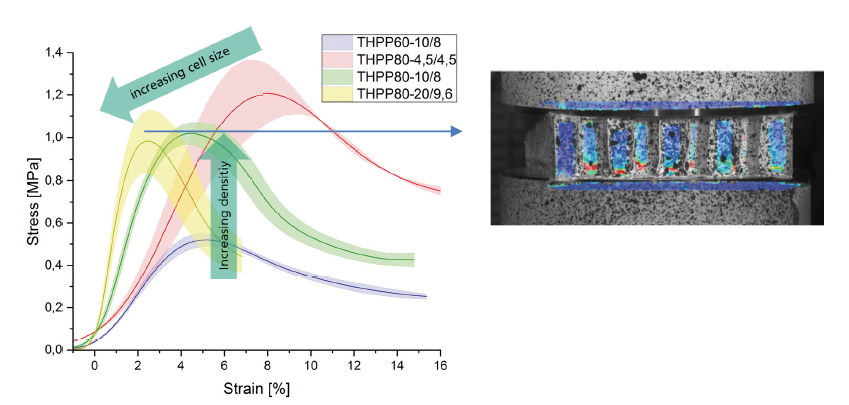

In tests carried out on honeycomb core materials of different densities (60 and 80 kg/m³) and also core height (4.5; 10; 20 mm) and cell size (4.5; 8; 9.6 mm), the following tendencies are observed in the compression properties measured; as the core density rises (respectively increasing cell wall thickness) the compressive modulus and compressive strength of the core increase. As core height and cell size increase, the compressive modulus increases while compressive strength falls.

Shear tests

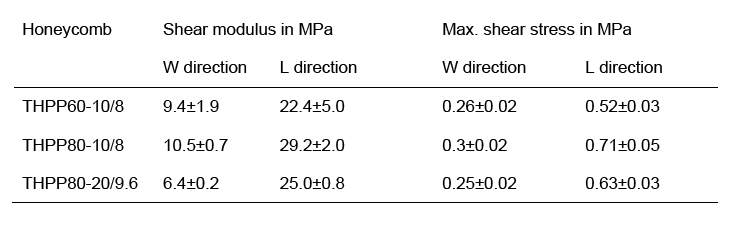

The shear tests were carried out on the basis of ASTM C273M as a tensile plate shear test. Here the cuboid sandwich test pieces were bonded to two load introduction plates. Shearstress/shear-strain curves were calculated from the force signal of the testing machine and the optically measured relative displacement of the test piece. Specimens were tested in each case in the W and L directions of the honeycomb core.

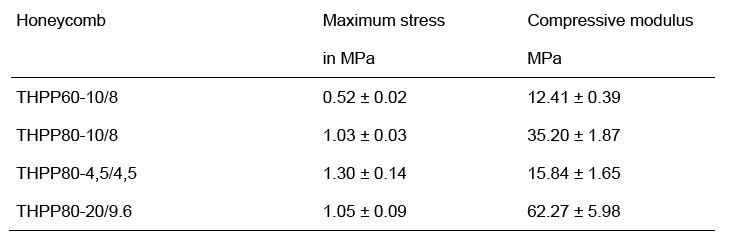

Fig. 3 shows the shear-stress/shear-strain curves measured. Depending on the test direction, significant differences in shear behavior can be seen. In the L direction, shear moduli up to three times higher occur. The first stress maximum in the L direction is about twice as high. In addition, influences of the honeycomb core density (here 60 and 80 kg/m³) as well as the core height and cell size can be seen. With an increase in the core density, an increase of the shear modulus and also the first stress maximum occur for both test directions and the same core height and cell size. Increasing both core height and cell size but keeping the same core density leads to a decrease in the shear modulus and stress maximum. This is especially evident when testing in the W direction and can be attributed to the deformation mechanisms involved and the special nature of the ThermHex honeycomb core with its partly unconnected cell walls in the W direction.

Flexure tests

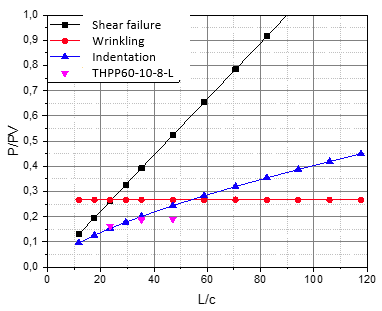

The flexure tests on Organosandwich test pieces were carried out on the basis of ASTM C393 as 3-point flexure tests. For this purpose, appropriate sandwich specimens were tested with different support distances (200, 300 and 400 mm). During the tests, the center deflection of the test piece was measured by means of an extensometer. In the tests with a short support distance, it was often possible to observe a shear failure of the core and, in the case of honeycomb cores of lower density (60 kg / m³) or greater core height and cell size, also local indentation of the core in the area of the upper support. In the case of larger span lengths, however, a failure of the upper, pressure-loaded top layer (top-layer wrinkling) was often observed.

The flexural failure loads determined at different span lengths were plotted in a diagram as normalized failure loads against span length and sandwich height. These so-called failuremode maps can provide information about which sandwich configuration (core density, core height, skin layer material) should be selected for a particular application (span length) for a given load. Here, in addition to the measured values, additional graphs are prepared for the different types of sandwich failure (including local core indentation, top layer wrinkling, shear failure of the core). In this way, the skin layer and the core can be mutually adjusted as efficiently as possible. Ideally the honeycomb core should have mechanical properties high enough to allow the best possible exploitation of the mechanical strength of the skin layer.

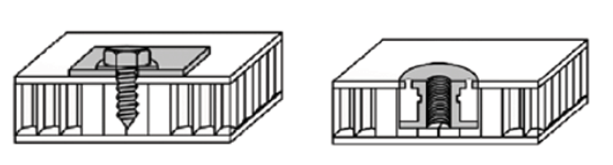

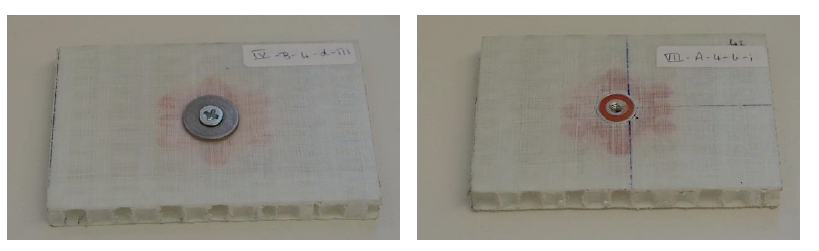

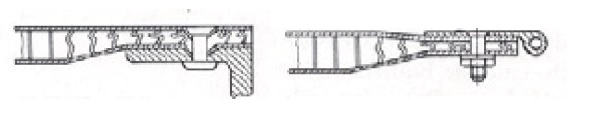

Injection molding of punctiform load-introduction elements

The relatively low strength of FRP sandwich structures in the thickness direction requires special adaptations in the joint area for punctiform load transfer, for example, by means of screws. Different connecting concepts may be found in the literature, which are applied depending on the load and application case. For medium and high loads the core structure must be reinforced locally, which can be done, for example, by filling the core with a curable resin-catalyst compound, known as potting. Depending on the load case, additional metallic inserts are embedded in the potting material (fig. 4 and 5).

During the processing of Organosandwich semi-finished products in the hybrid injection molding process, it is possible to use injection molding and thermoplastic for the potting fillings. It has already been demonstrated in experimental studies that a reproducible filling of a previously prepared core area by means of an adapted injection-molding cycle is possible within a few seconds. As an injection-molding material for the plastic potting, polypropylene with an MFI of 23g/10min, appropriate for the matrix material of the Organosandwich semi-finished products, was processed in the experiments. Not only could pure potting fillings be produced by injection molding but metallic inserts could also be embedded in the sandwich.

Edge melting

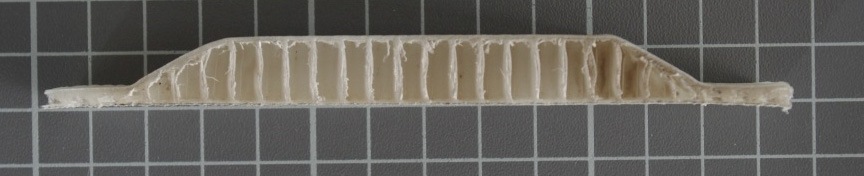

In addition to the design freedom in the shape of the component, the provision of joining concepts is an important aspect in establishing endless-fiber-reinforced thermoplastic sandwich composites as structural components in high-volume applications. With sandwich structures relatively great effort is necessary for the preparation of the joint locations in order to connect them using established joining methods such as welding, riveting or adhesive bonding, for example, to load-bearing structures (Fig. 6).

Fusing the face layers into a single monolithic laminate is a method which makes it possible to prepare the joint location on sandwich structures. In this way the joining processes mentioned can then be used without additional connection profiles. The skin layers can be brought together into a single monolithic laminate especially at the edges of sandwich structure components. A chamfer can serve as a transition between the sandwich structure and the monolithic edge and should have a slope not exceeding 30°. In this way, under loading conditions the flow of force can be routed from the two skin layers via the core, with decreasing magnitude, into a load-bearing structure (Fig. 6 and 7).

During hybrid processing of the Organosandwich semi-finished products, the edge areas of the sandwich composite can be pressed into a monolithic laminate in addition to forming. For this purpose, validation tests have already been carried out with the test stand described in the section on hot forming and a specially designed punch. In the experiments, a flat Organosandwich sample is provided with the bevel geometry. Heating in the infrared radiation furnace is carried out with the same heating regime used for thermoforming the shell geometry. However, during the pressing process at the end of the tool closing movement, the heat stored in the skin layers is used to melt the honeycomb core into the monolithic laminate under increased pressure.